-40%

SUBLI-PRINT Heat Transfer Paper 100Sh 8.5X11" Great Easy Patches! Good on Cotton

$ 97.41

- Description

- Size Guide

Description

Subli-Print® is a heat-sealable, white polyester fabric with a twill-like feel. It can be printed on directly with sublimation ink. Great for creating easy patches!Product Details

Features: For use on cotton, uncoated polyester, and fabric blends.

Subli-Print Twill For Garments Application Instructions

General Use

Subli-Print is for 100% cotton, uncoated polyester, and fabric blends. For use with sublimation inks to achieve a full color image.

Printing

Print the image right reading.

Trim the excess white from the design with a cutter or scissors.

Transferring To Garments

Peel off backing.

Place your print face up on your shirt.

Press at 375°F for 30 seconds with low to medium pressure.

Transferring To Heat Sensitive Garments

After printing, pre-activate sublimation inks by pressing with silicon paper on top of design for 375 F for 30 seconds with low pressure.

Peel off backing.

Place your print face up on your shirt.

Press at 320°F for 15 seconds with medium pressure.

Washing Instructions

Wash inside out on gentle cycle, warm or cold water.

Tumble dry.

Do not dry clean.

No bleach or aggressive cleaning agents.

SUBLI-Print Dye Sub Inkjet Heat Transfer Paper 8.5 x 11 Sheets

Heat-sealable, printable Polyester fabric (white) specially developed for sublimation print.

SUBLI-Print has a self-adhesive polyester film on the hotmelt side and can be used for dye-sublimation transfer-printing. Motives and Logos can be cut by all current CAD/CAM plotters after printing.

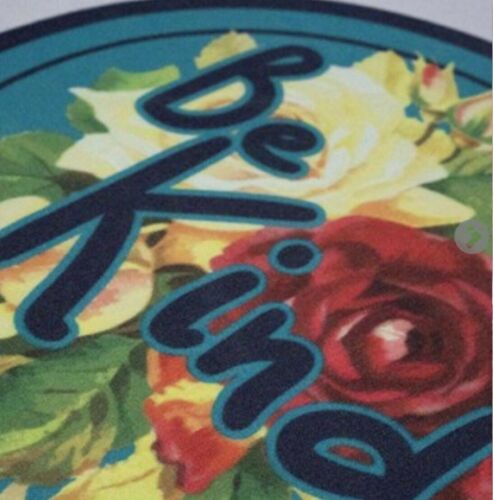

SUBLI-Print is used for lettering on Sport and leisure wear. Final printed motives and logos are bright and colourful due to the homogeneous surface.

Nylon and textiles with a hydrophobic impregnation are not suitable for heat transfer.

Application

• Print directly onto the Polyester fabric with a dye sublimation printer. Cut and weed the motive.

• For heat sensitive textiles, we recommend to activate the sublimation ink by placing the motive in between silicone paper (351) and heat- press at 190 °C under low pressure for 30 seconds.

• The motive can then be transferred to the textile at 160 °C, 2,5 - 3,0 bar for 15 seconds

• For textiles where high temperature can be applied, transfer in one step at 190 °C, low pressure for 30 seconds. Technical DataTransfer Film: Adhesive: Thickness [mm]: Liner: Transfer ConditionsTemperature: Pressure: Time: Polyester fabric Copolyester-hotmelt 0,42 +/- 5 % PET film, self-adhesive 160 °C 2,5 - 3,0 bar [medium pressure]15 sec. Wash Resistance / Printing Wash resistance: Printing: Safety Data Sheet 40 °C Only colour or mild detergent. Wash textiles inside out. Tumble dryable. only direct

#subliprint

#Subli-Print

#sublicotton

#dyesub

#dyesubprint

#dyesubprinting

#sublimation

#sublimacion

#estampacion